Views: 0 Author: Site Editor Publish Time: 2025-08-08 Origin: Site

In 2025, stainless manifolds are the best pick for most jobs. They are great when you need something that lasts a long time. They also work well where rust is a problem. Carbon steel manifold choices are still common in oil, gas, and factories. This is because they are strong and do not cost too much.

Quick Comparison:

Stainless: Stops rust very well, good for wet or rough places like turbo systems.

Carbon steel: Very strong, saves money, and works for many uses like manifolds and turbos.

You should pick your manifold based on what your project needs. Think about where you will use it and how much you can spend. Jiangsu Easywell Smart Products Co., Ltd. sells both stainless and carbon steel manifolds. Many people in different jobs trust their products.

Stainless steel manifolds do not rust and last a long time. They work best in wet, chemical, or tough places. Carbon steel manifolds are strong and cost less at first. They are good for dry or easy jobs with small budgets. You should pick a manifold based on your project's place, fluid, heat, pressure, and money. Cleaning and checking manifolds often helps them work well. This also stops big repairs or problems. Over time, stainless steel saves money. It needs fewer fixes and changes, even if it costs more at first.

Carbon steel and stainless steel manifolds are different in many ways. These differences matter for exhaust headers, turbo systems, and boost. Stainless steel manifolds work well in tough places. They do not rust easily and can handle heat. This helps keep power and boost steady. Carbon steel manifolds are strong and cost less money. Many companies use them for turbo and exhaust headers when they want to save money.

Here is a table that shows the main differences:

Aspect | Stainless Steel Manifolds | Carbon Steel Manifolds |

|---|---|---|

Corrosion Resistance | High corrosion resistance, good for tough places | Lower corrosion resistance, needs coatings |

Durability | Very durable, handles heat and pressure well | Strong but not as good in wet places |

Typical Applications | Used in oil, gas, and chemical jobs with hard conditions | Used where things are easier or coatings are used |

Strength-to-Weight | Strong but not heavy | Strong but heavier |

Maintenance | Easy to take care of, gets better with new tech | May need more care or protection |

Cost | Costs more because of better material and performance | Cheaper, good for saving money |

Stainless steel manifolds have chromium. This makes a film that stops rust. It keeps exhaust headers safe and helps turbo boost stay strong. Carbon steel manifolds are tough and simple to use. They do not stop rust or heat as well as stainless steel. But they still work well for many turbo and exhaust jobs.

Pick stainless steel manifolds for turbo headers and exhaust systems in wet or chemical places. These manifolds keep boost high and help waste-gate work better. They last longer in hot turbo setups. Stainless steel is best for welded and cast turbo manifolds that need to work very well.

Pick carbon steel manifolds for turbo and exhaust headers in dry or easy places. They give strong power and boost for less money. Many people use carbon steel for cast and welded turbo manifolds in factories or when saving money is important. Carbon steel manifolds can handle high power and boost. But they need coatings to help waste-gate work better.

Tip: If you want the best boost and turbo power, pick stainless steel manifolds. If you care more about saving money and having good exhaust headers, carbon steel manifolds are a smart choice.

A carbon steel manifold works well in many systems. But it does not fight rust very well. When water and carbon dioxide are around, rust can happen fast. Carbon dioxide mixes with water and makes carbonic acid. This acid can eat away at the metal. In factories or places with hot and cold changes, this rust can cause a lot of metal to go away. To help stop this, engineers make the manifold thicker, sometimes by 3 mm, to protect it.

Many jobs use coatings to help carbon steel manifolds last longer. Some coatings are powder coating, e-coating, and nanocoatings. These coatings make a wall that keeps water and chemicals out. Some new coatings, like EonCoat, stick to the steel and make a strong shield. This shield can even fix itself if it gets hurt, so it protects for a long time. The table below lists some coatings and what they do:

Protective Coating/Treatment | Description | Application/Advantages |

|---|---|---|

Electroplating (Nickel, Chrome) | Thin metal layers go on top; helps stop water and wear. | Used in homes and small jobs; looks nice; lasts longer if thicker. |

Polymer and Epoxy Coatings | Strong barriers that stick to metal; bend when hot or cold. | Used in heating and big jobs; stops damage from pH, salt, and germs. |

Passivation (Stainless Steel) | Chemical wash makes a chromium-rich layer. | Helps stop rust in salty places; used in boats and chemical jobs. |

Physical Vapor Deposition (PVD) | Hard metal layers put on in a vacuum. | Gives the best rust and scratch protection; used in important jobs. |

Stainless manifolds are great at stopping rust. The reason is the chromium inside. Stainless steel has at least 10% chromium. This makes a thin layer on top called chromium oxide. The layer acts like a shield and blocks rust. If the surface gets scratched, the layer fixes itself and keeps the manifold safe.

In places like boats, factories, and homes, stainless manifolds rust much less than carbon steel. Some stainless types have up to 27% chromium. These types fight rust even better and help stop cracking from stress. But in salty places near the sea, stainless can still get some rust, like chloride stress cracking. Still, for most jobs, stainless manifolds are strong and fight rust well. This makes them a good pick for systems that need to last and work in hard places.

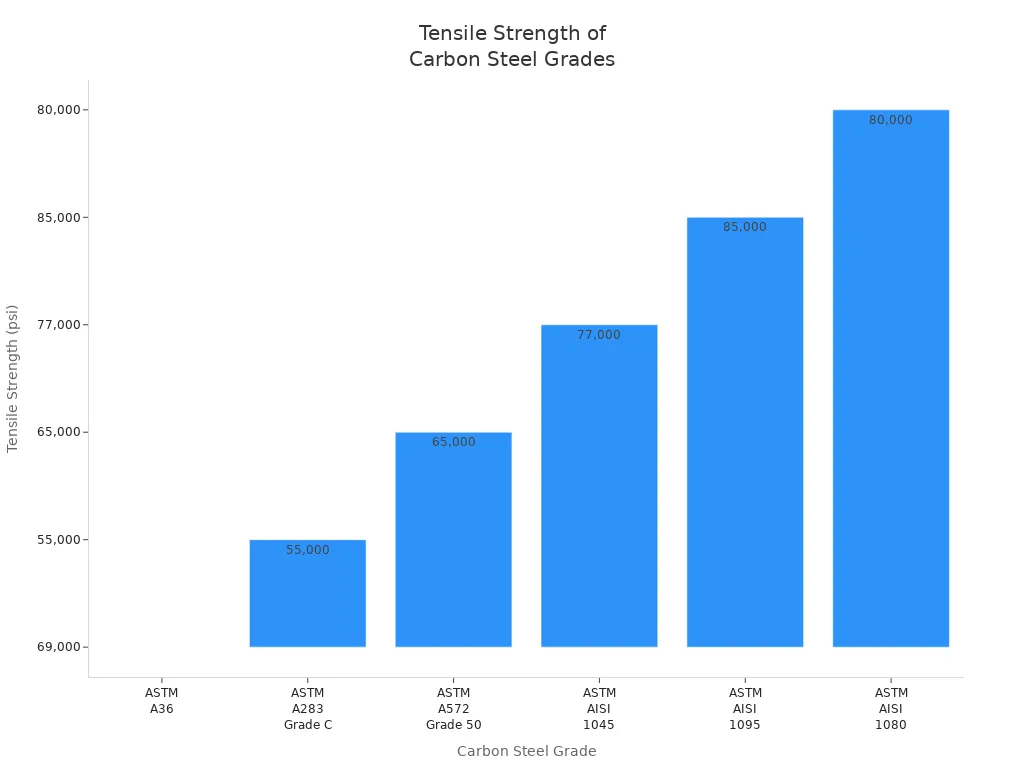

How strong a manifold is matters a lot. Carbon steel manifolds come in many types. Each type has its own strength. The table below shows how strong some carbon steel grades are:

Carbon Steel Grade | Carbon Content (%) | Tensile Strength (psi) | Yield Strength (psi) |

|---|---|---|---|

ASTM A36 (Low Carbon) | < 0.25 | 58,000 – 80,000 | Not always specified |

ASTM A283 Grade C | Low Carbon | 55,000 | Not specified |

ASTM A572 Grade 50 | Medium Carbon | 65,000 | Higher than A36 |

ASTM AISI 1045 | Medium Carbon | 77,000 | Not specified |

ASTM AISI 1095 | High Carbon | 85,000 | Not specified |

ASTM AISI 1080 | High Carbon | 80,000 | Not specified |

Stainless steel manifolds like 316 or 316L are also strong. Their tensile strength is between 75,000 and 100,000 psi. Their yield strength starts at 30,000 psi. This means stainless steel can take a lot of pressure. It is a good pick for many jobs.

Longevity tells us how long a manifold will last. Stainless steel manifolds, like AISI 347, last much longer than carbon steel. They do not crack or rust easily. They also do not break down from heat. The chromium and nickel in them make a layer that fixes itself. Niobium in AISI 347 helps stop rust at the edges of the metal. This keeps the manifold strong after many hot and cold cycles.

Property | Cast Iron / Mild Steel Manifolds | AISI 347 Stainless Steel Manifolds |

|---|---|---|

Thermal Fatigue Resistance | Poor to Very Poor | Excellent |

Corrosion Resistance | Poor to Low | High |

Lifecycle (Service Life) | 20,000–50,000 km | Over 100,000 km |

Structural Integrity | Prone to cracking and scaling | Maintains integrity |

Resistance to Sulfidation | Low | Excellent |

Performance in Harsh Conditions | Cracks and corrodes easily | Retains strength |

AISI 347 stainless steel manifolds are very tough. They can go through over 100,000 hot and cold cycles with little damage. This means they break less and need less fixing. Stainless steel manifolds work well in hard places, like near the ocean or in chemical plants. Carbon steel manifolds may need more care and do not last as long in rough spots.

Turbo systems and exhaust headers get very hot when working. Both carbon steel and stainless steel manifolds must handle this heat. This keeps everything working well. The table below shows how hot each material can get:

Material | Maximum Operating Temperature |

|---|---|

Carbon Steel | 1,000 °F (538 °C) |

316 Stainless Steel | 1,000 °F (538 °C) |

Both materials can take the heat from turbo exhaust. Mild steel, which is a kind of carbon steel, sometimes handles even more heat before it changes. This makes carbon steel manifolds a good pick for turbo headers in cars and race cars. Stainless steel manifolds do not rust and keep power high, even when things get hotter. In turbo setups, good heat performance helps keep boost and quick response. If a manifold stays strong in heat, turbo power and exhaust flow stay steady.

Thermal expansion means manifolds grow and shrink when heated and cooled. This can change how long they last and how well they work. Here are some important things to know:

Stainless steel manifolds expand less than many other materials. This can make stress at the joints when they heat and cool.

Stainless steel can crack from heat and weld stress because of its makeup and lower stretchiness when hot.

Carbon steel manifolds, like mild steel, handle heating and cooling better. They do not crack or bend as much, so they are good for daily turbo use.

Mild steel manifolds usually line up better and do not bend much when made. This helps exhaust headers and turbo systems work well.

Different expansion rates mean you must design the system to handle stress and stop breaks.

For street and race turbo jobs, mild steel manifolds give strong results, cost less, and last longer with heat cycles.

Stainless steel manifolds are strong and do not rust, but need careful making to stop heat cracks. This can change how long they last and how much care they need.

Note: Picking the right manifold material helps keep turbo boost, exhaust flow, and power steady. Good heat performance means better boost and turbo headers that last longer.

When choosing a manifold, many people look at the price first. Carbon steel manifolds usually cost less than stainless steel manifolds. This lower price makes carbon steel a popular choice for projects with tight budgets. Factories and large buildings often use carbon steel because it helps save money at the start.

Stainless steel manifolds cost more to buy. The higher price comes from the special materials and extra steps needed to make them. Stainless steel contains chromium, which helps stop rust. This makes the material more expensive. For projects where the environment is harsh or where long life is important, many choose stainless steel even with the higher price.

Here is a simple comparison:

Manifold Type | Typical Upfront Cost | Main Reason for Cost |

|---|---|---|

Carbon Steel | Lower | Basic material, easy to make |

Stainless Steel | Higher | Special alloy, resists rust |

Tip: Carbon steel manifolds help save money at the start. Stainless steel manifolds cost more but offer extra benefits.

The real value of a manifold shows over time. Stainless steel manifolds last much longer than carbon steel ones. The chromium in stainless steel forms a shield that stops rust. This means stainless steel manifolds can last up to 20 years in good water conditions. They need only simple cleaning and checks.

Carbon steel manifolds do not last as long. They can rust and break down faster, especially in wet or rough places. This leads to more repairs and replacements. Over time, the cost to fix or replace carbon steel manifolds adds up. Stainless steel manifolds, on the other hand, need fewer repairs. They work well in harsh places and keep their strength for many years.

Note: Stainless steel manifolds may cost more at first, but they save money in the long run. Fewer repairs and replacements mean lower costs over the life of the system. Carbon steel manifolds cost less to buy but may need more care and replacement, which can raise the total cost over time.

Cleaning manifolds often helps them work better. Dirt and dust can pile up on the surface. If you do not clean it, this can cause corrosion. Workers use soft brushes or cloths to wipe off loose dirt. For sticky grime, they use mild soap and water. After washing, drying the manifold stops water spots and rust. Stainless steel manifolds need less cleaning because they fight corrosion well. Carbon steel manifolds need more cleaning, especially in wet or dirty places. Clean manifolds last longer and work better in heating, HVAC, and plumbing.

Manifolds can have some problems that need fixing. Carbon steel manifolds often get rust and corrosion. These problems can make the metal weak and cause leaks. If moving parts like stems and bearings do not get enough oil, they can stick or stop working. Seals and bearings can wear out after a while. Checking manifolds often helps find rust, leaks, or parts that do not line up. Workers should look at valve seats and check if pressure and temperature are safe. Repairs may mean putting in new seals or bearings. Only trained workers should do these repairs. Keeping good records of all work helps track how the manifold is doing and stops big problems. Stainless steel manifolds do not get as much rust, but checking them often still helps them last longer.

Tip: Cleaning and checking manifolds often stops most problems and keeps them working well.

A carbon steel manifold works well in hard places. Factories use it in steam systems and oil or gas pipes. These places need strong parts for high heat and pressure. In heating and HVAC, it moves hot water or steam around buildings. Construction sites pick this manifold because it is cheap and works well. Power plants and water plants use carbon steel for its strength and long life.

Carbon steel manifold is used in:

Steam and hot water heating

Oil and gas pipes

Water and sewage systems

Power plants

This manifold can handle high-pressure exhaust systems. It is strong and lasts a long time. That is why big projects often use it.

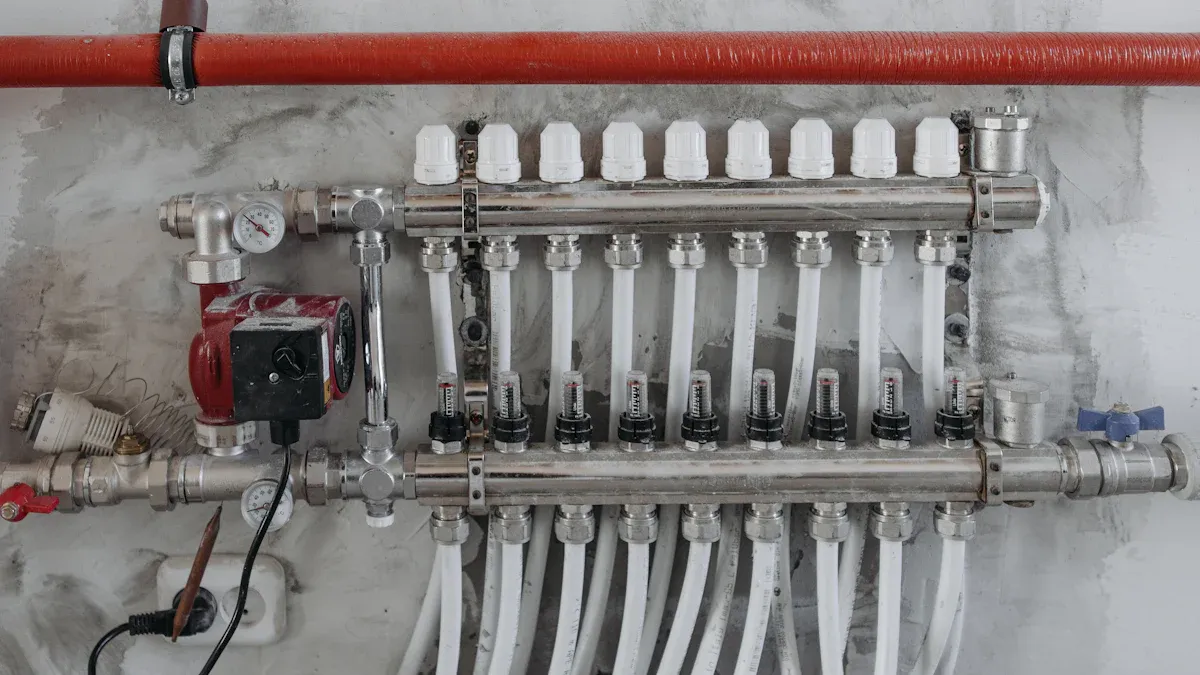

Stainless manifolds are used where things must stay clean. They also last a long time. Homes and businesses use them in heating, like underfloor and radiant heating. These manifolds help control hot water or coolant in HVAC and cooling. Factories that make food, medicine, or chemicals use stainless manifolds. They do not rust and keep fluids clean. Data centers and clean rooms use them for safe fluid control.

Stainless manifolds are used in:

Home and business heating

Cooling and air conditioning

Food and drink factories

Medicine and biotech plants

Drinking water and clean water systems

Solar heating and other green energy

Car exhaust and fuel systems

Jiangsu Easywell Smart Products Co., Ltd. makes steel manifolds for homes and factories. Their manifolds work with expansion tank brackets. They use strong steel and special coatings. These help the manifold stay strong in heat and wet places. The mounting system makes it easy to install, even in busy boiler rooms or chemical plants. This makes Easywell’s manifolds a good pick for many exhaust and fluid jobs.

Project managers and engineers need to think before picking a manifold. Asking the right questions helps you choose the best material. This can stop mistakes that cost a lot of money.

What kind of place will the manifold be in?

Wet, hot, or chemical-filled places can make manifolds wear out faster. Stainless steel is best for wet, salty, or chemical spots. Carbon steel is good for dry, indoor, or easy places.

What will move through the manifold?

Water, oil, gas, or chemicals all need different care. Stainless steel stops rust and keeps fluids clean. This is important for food, medicine, and clean water jobs.

How much does rust matter?

If the manifold will get wet or touch chemicals, stainless steel is safer. Carbon steel needs coatings and more care in these places.

How long should the manifold last?

If you want it to last many years, pick stainless steel. Carbon steel is fine for short jobs or if you plan to replace it often.

How much money can you spend?

Carbon steel costs less at first but may need more fixing. Stainless steel costs more but saves money later.

How much pressure and heat will there be?

Both carbon steel and stainless steel can take high heat and pressure. Always check the ratings to be sure.

Are there any rules or marks needed?

Look for ASME or IECEx marks for safety and quality. These are important for turbo or control systems.

Tip: Always ask suppliers about the grade of stainless steel, quality checks, and if the manifold meets standards like ASME or ISO 9001. This helps make sure the manifold is safe for turbo and control jobs.

Here is a table of key questions to ask suppliers:

Key Question Area | Details to Ask Supplier |

|---|---|

Material Quality & Standards | What grade of stainless steel is used (e.g., 304/304L, 316/316L)? Can you provide Mill Test Reports? |

Standards Compliance | Do your products meet ASTM, ASME, or other relevant standards? |

Certifications & Quality | Do you have ISO 9001 certification? What quality control steps do you perform? |

Supplier Experience & Expertise | How long have you been in business? Can your team help with material selection? |

Inventory & Availability | Do you keep a large stock? Can you make custom manifolds for turbo or control needs? |

Lead Times & Delivery | What are your typical lead times? How do you handle urgent turbo orders? |

Customer Service & Reliability | Can you share client reviews or case studies? How do you ensure on-time delivery and clear communication? |

A simple checklist helps you not miss anything when picking a manifold for turbo, heating, or control systems. Use this list to help you remember what to check:

Check the environment

Is the area wet, salty, or full of chemicals?

Pick stainless steel for tough places. Use carbon steel with coatings in dry, safe spots.

Match the material to the fluid

Will the manifold carry water, oil, or chemicals?

Stainless steel keeps fluids clean and stops rust. This is key for food, medicine, and clean water.

Review pressure and temperature needs

Does the turbo system get hot or have high pressure?

Make sure the manifold can handle it.

Plan for service life

How long do you want the manifold to last?

Stainless steel lasts longer, especially in turbo and control jobs.

Consider cost and value

Is the project short or long?

Carbon steel saves money now. Stainless steel saves money later because it needs fewer repairs.

Check for standards and certifications

Does the manifold meet ASME, IECEx, or ISO 9001?

This is important for safety in turbo and control systems.

Ask about supplier support

Can the supplier help with design, testing, and fast delivery?

Good support means fewer problems when you install and use it.

Avoid common mistakes

Never mix metals without checking for rust problems.

Do not forget about the environment or skip regular checks.

Always match the manifold to the turbo and control system needs.

Note: Many places, like food, medicine, and chemical plants, use stainless steel manifolds because they fight rust and last a long time. Turbo systems in cars and factories also need the right manifold to keep power and control steady.

Checking these points helps make sure the manifold will work well in any turbo or control job, whether at home, in a factory, or in a high-tech plant.

In 2025, experts say carbon steel manifolds save money. They are used a lot in oil and gas jobs. Stainless manifolds work best in tough or chemical places. These places need strong protection from rust. Stainless manifolds also follow strict safety rules in many jobs. Before picking a manifold, think about what you need. Look at how much you will make, how hard the design is, and the cost. Stainless manifolds last a long time and keep people safe in high-pressure or chemical work. To choose the right one, talk to trusted suppliers like Jiangsu Easywell Smart Products Co., Ltd.

Carbon steel manifolds are strong and cost less. Stainless steel manifolds do not rust and last longer in tough places. Each type is good for different projects.

Engineers put coatings on carbon steel manifolds to protect them in wet spots. Stainless steel manifolds are better in damp places because they do not rust as easily.

Experts say to check steel manifolds at least once every year. Regular checks help find leaks, rust, or other problems early.

Yes. Easywell’s steel manifolds have brackets and mounting systems that fit well. These parts make it easy to install them at homes or in factories.

Stainless steel manifolds usually save more money over many years. They need fewer fixes and last longer, even in hard places.