Jiangsu Easywell provides a complete selection of steel manifolds engineered for heating, cooling, and hydronic applications. Built for reliability, precision, and long service life, our steel manifolds are widely used in residential heating, commercial HVAC, and multi-line industrial systems.

Each manifold is fabricated from high-strength carbon steel or precision-welded stainless steel, ensuring exceptional resistance to pressure, corrosion, and mechanical stress. These manifolds deliver uniform fluid distribution across multiple circuits — a key factor in system efficiency and temperature stability.

Durable Construction: Built with thick-walled carbon steel for long-term resistance to heat and corrosion.

High Flow Efficiency: Smooth internal surfaces minimize pressure loss, ensuring consistent flow in each circuit.

Precise Engineering: Threaded or welded ports (½″–1″) allow secure connections with hydronic components.

Universal Compatibility: Easily integrates with expansion tank brackets, heating pumps, and pressure balancing systems.

Cost-Effective Solution: Offers the perfect balance between performance and affordability for standard HVAC setups.

| Product Name | Description | Typical Application | Key Specifications |

|---|---|---|---|

| Basic Hydronic Manifold for Residential Heating | Compact steel manifold designed for small to mid-size heating systems. Provides stable flow and temperature distribution. | Floor heating, radiator loops, small hydronic circuits. | Size: 250 mm length · Ports: ½″ × 4 – 8 loops · Max pressure: 10 bar. |

| Precision-Engineered Manifold System for Multi-Line Fluid Control | Advanced manifold featuring balanced multi-line flow design and modular connection options. | Commercial HVAC, chilled water, and multi-zone systems. | Size: 280 mm length · Ports: ½″ / ¾″ · Working temp: –20 °C – +120 °C. |

This technical drawing illustrates the standard configuration of the Basic Hydronic Manifold, ideal for residential heating systems.

The manifold features a compact dual-bar design with uniformly spaced outlets for consistent fluid distribution.

Key dimensional details:

Total length adjustable according to loop number (6–12 circuits).

Outlet spacing: 35.5 mm per port, ensuring even flow across circuits.

Mounting height: 25 mm, suitable for compact wall-mounted installations.

End connection dimensions: G ¾″ inlet/outlet, with G ½″ branches for distribution lines.

Integrated support brackets designed for quick wall or cabinet installation.

Application note:

This model is optimized for floor heating and small hydronic circuits, balancing simplicity with efficiency. The tight spacing minimizes system footprint, making it ideal for residential or retrofit installations.

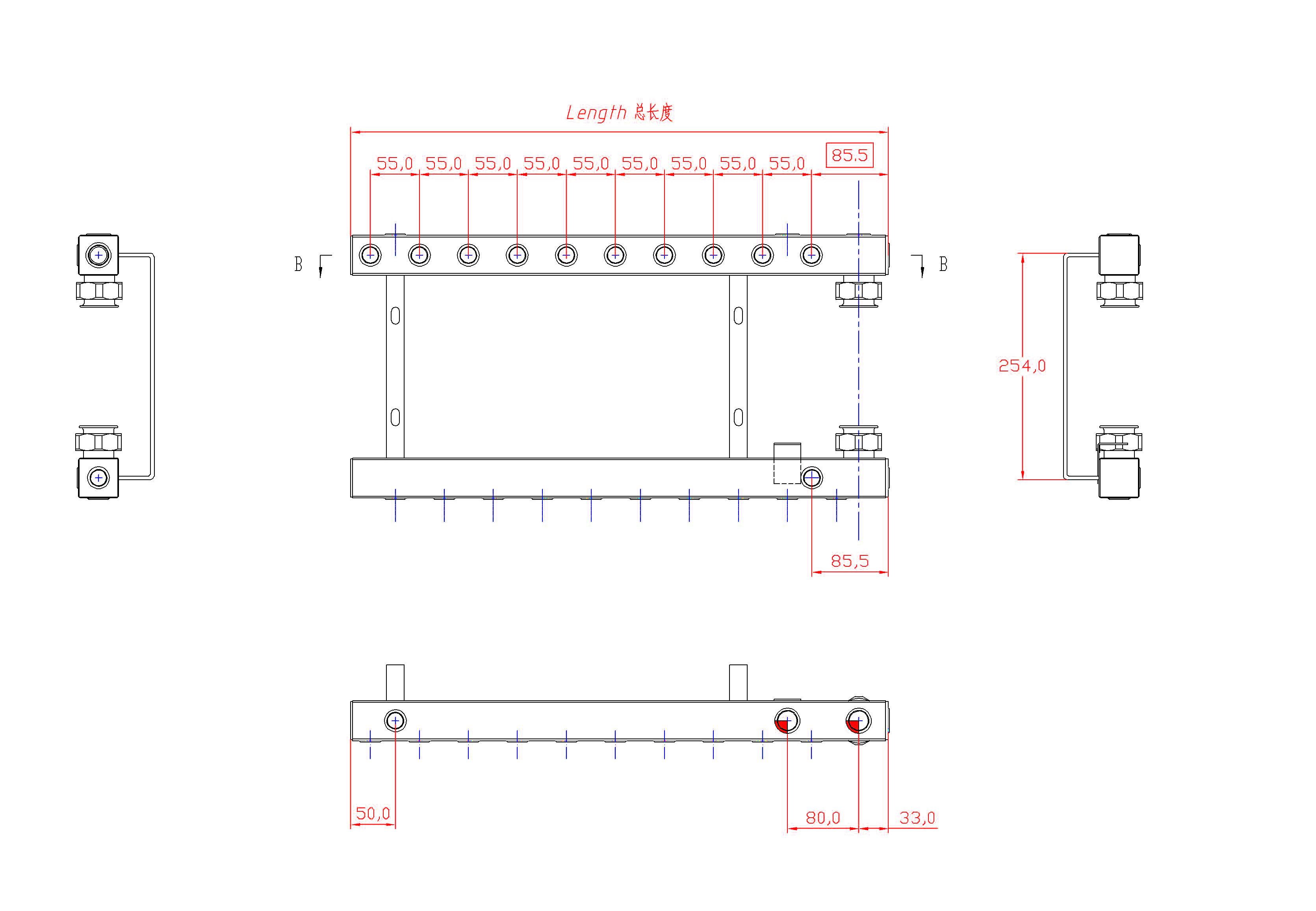

The following layout presents the multi-line configuration of the Precision-Engineered Manifold System, developed for commercial or modular hydronic setups.

Key dimensional details:

Total length customizable (4–8 loops).

Port spacing: 55 mm between branches, enabling optimal flow balance and easy valve integration.

First and return tube offset: 34 mm for improved separation and system pressure control.

End connections: G ¾″ inlet/outlet and G ½″ branches.

Compact design with a 4 mm wall thickness, ensuring mechanical rigidity under high pressure.

Application note:

Designed for multi-zone heating, cooling, and industrial liquid circuits, this manifold provides precise flow adjustment and flexible system scalability. Its engineering-grade layout supports integration with smart control valves and temperature sensors for advanced system automation.

Material: High-strength carbon steel (zinc-plated or powder-coated finish).

Port Configuration: Top – 3/8″ / ½″ / ¼″; Bottom – 2 × ¾″ outlets.

Mounting Options: Wall-mounted or in-panel installation with standard brackets.

Working Pressure: Up to 16 bar / 232 psi.

Temperature Range: –20 °C – +120 °C.

Surface Treatment: Anti-corrosive coating for enhanced lifespan.

Residential Heating Systems – Provides efficient temperature control in floor and radiator systems.

Commercial Buildings – Suitable for HVAC water balancing, heat exchanger loops, and central heating.

Industrial Fluid Control – Used in process water, coolant, and hydraulic fluid distribution.

Renewable Energy Systems – Compatible with solar thermal and geothermal manifolds for closed-loop operation.

Installation: Mount the manifold horizontally with even spacing to ensure uniform pressure.

Connection: Use compatible brass fittings or PEX adaptors for leak-free joints.

Pressure Test: Perform a 24-hour leak test before system commissioning.

Maintenance: Clean filter screens regularly; inspect gaskets every 12 months.

Replacement: In high-humidity or corrosive environments, choose zinc-coated or stainless versions.

| Feature | Steel Manifold | Brass Manifold | Plastic Manifold |

|---|---|---|---|

| Durability | ★★★★★ | ★★★★☆ | ★★☆☆☆ |

| Pressure Resistance | Up to 16 bar | Up to 10 bar | Up to 6 bar |

| Cost Efficiency | Excellent | Moderate | High |

| Thermal Expansion Stability | Excellent | Good | Poor |

| Corrosion Resistance | Very Good | Good | Fair |

This clear comparison highlights why steel manifolds are the preferred option for heating and industrial fluid systems.

Steel manifolds handle higher pressures and temperatures, making them ideal for industrial and large heating systems. Brass manifolds are suitable for small residential installations.

Yes, they perform excellently in cooling loops and mixed-temperature systems due to their corrosion-resistant coating.

Absolutely — Easywell steel manifolds connect seamlessly with our expansion tank brackets and vessel supports.

With proper installation and periodic maintenance, service life exceeds 15 years even under continuous operation.