Views: 0 Author: Site Editor Publish Time: 2025-08-08 Origin: Site

A steel manifold is like a main center in many factories. It controls how liquids or gases move by linking pipes with valves and ports. This part is very strong because it is made from steel or stainless steel. It helps things run smoothly and keeps people safe. Many industries use steel manifolds to move fluids and gases safely. The world market for steel manifolds was about $3.5 billion in 2023. This market is still getting bigger.

Steel manifolds join many pipes together. They help control how liquids and gases move. This keeps things safe and works well in factories and buildings.

Steel is the best material for manifolds. It is very strong and does not rust easily. Steel can also handle high pressure and heat.

Manifolds help save energy and stop leaks. They make systems easier to fix by organizing flow paths. Smart controls also help with this.

There are different types of steel manifolds. Some are in-line and some are smart versions. They work for many needs, like heating or big factories.

Steel manifolds are used in many places. They are in heating, water, car, and factory systems. They last a long time and help keep things safe.

A steel manifold works like a main center in many factories. It links many pipes together and helps control how liquids or gases move. Engineers make each manifold strong for tough jobs and high pressure. The main part uses carbon steel or stainless steel. These materials make it strong and stop rust.

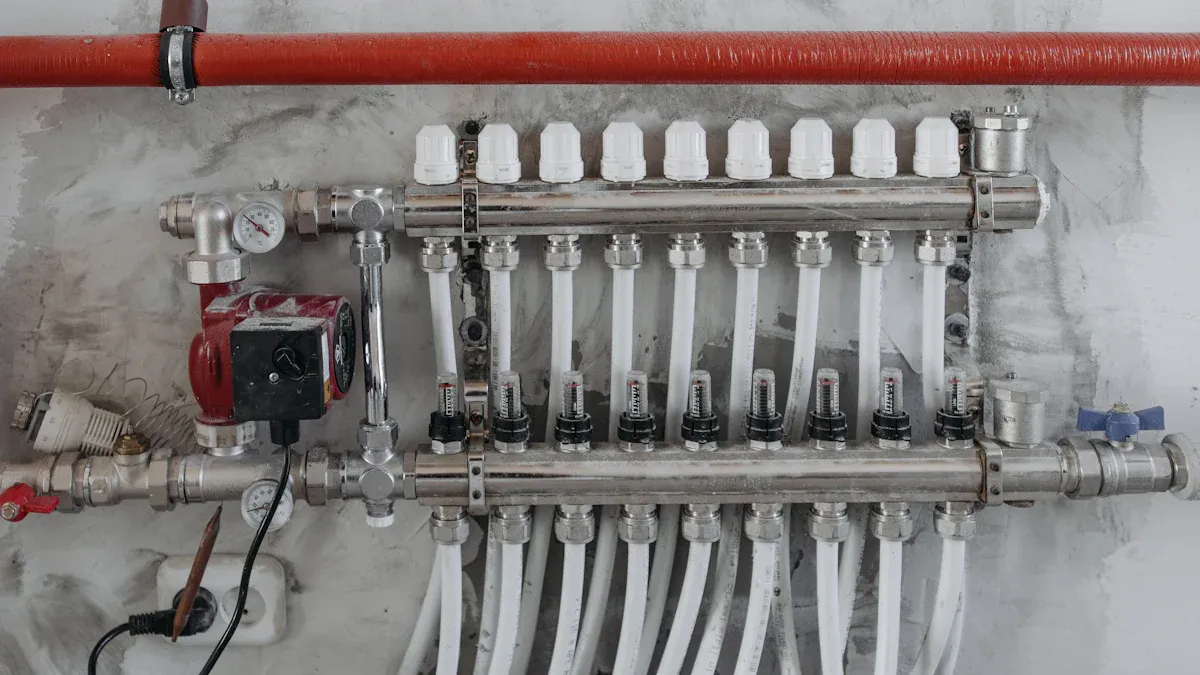

A steel manifold often looks like a thick block with many holes and valves. These holes let fluids or gases go in and out safely. Its small size saves space and makes it easy to put in, even in tight spots.

Easywell’s Steel Manifold series shows how new designs make these parts better. Each one uses strong carbon steel. The design stops leaks and fights rust. Easywell adds things like brackets for tanks and vessels. These extras help keep the system steady and simple to use.

Here is a table that lists the main parts and features of steel manifolds used in factories:

Component/Feature | Description |

|---|---|

Design Types | Monoblock (compact, strong), Connecting plates (modular), Longitudinal linking (saves space), Vertical stacking (efficient) |

Material Options | Steel (very strong, resists rust and wear), Cast iron, Aluminum (lightweight) |

Key Design Features | Small size, few seals, modular, saves space, very safe and reliable |

Pressure Ratings | Steel can handle up to 420 bar |

Application Benefits | Exact control of fluids, less fixing needed, fits complex systems |

The main job of a steel manifold is to guide and control how liquids or gases move. It brings many pipes together into one system. This makes it easy to watch and control the whole process. Each manifold can have valves, gauges, and places to check pressure or temperature.

A steel manifold does many important things:

Controls where and how fast fluids or gases move.

Sends fluids or gases to different parts of a system.

Shuts off parts for fixing or in emergencies.

Checks how the system works with built-in gauges.

Makes moving fluids and gases safer and more efficient.

Engineers pick steel for manifolds because it can take high pressure and does not get damaged by chemicals. The smooth inside helps stop leaks and keeps the flow steady. Modular designs make it easy to change or upgrade the system.

Easywell’s Steel Manifold series is special because it has all these good features. The manifolds work well in heating, water, and big factory systems. Their strong build and smart design make them a good choice for many uses.

A steel manifold is the main part in many factory systems. It has many important parts that work together to move fluids and gases. The base holds everything and often has feet that can be moved for balance. Manifold pipes connect different areas, so liquids or gases can move easily.

Key parts include:

Valve clusters that let fluids in or out of the pipes.

Pipes with strong joints to link tanks or machines.

Air connectors that help get rid of trapped air.

Cable guides and electric panels to keep wires safe and neat.

Trays and walkways for easy fixing and use.

Sensors and gauges inside to check pressure and temperature.

Valves are very important because they control many other valves in the manifold. Some systems use mixproof valves with two seats and gaskets. These parts stop different fluids from mixing. Inside, drilled holes make paths for fluids to move. These paths can look like U, Z, π, or + shapes. Each shape changes how the pipes move fluids and handle pressure.

The material used for pipes and valves is important. Steel and stainless steel are very strong and do not rust. They can take high heat and pressure, so they are good for tough jobs. Some systems use aluminum or cast iron, but steel is best for strength and long use.

Material | Key Properties and Applications | Pressure Tolerance | Machinability and Notes |

|---|---|---|---|

Steel | Very strong, good for high pressure and tough jobs, cools well | Up to 420 bar | Hard to shape, needs special tools; lasts a long time |

Aluminum | Light, does not rust, good for low pressure, cools well | Up to 210 bar | Easy to shape, costs less to make; good for moving machines |

Cast Iron | Strong, stops shaking, good for big machines and tough jobs | Up to 420 bar | Breaks easily, hard to shape; used for machines that stay in one place |

Manifolds are often made special for each job, depending on how many tanks there are and if they need to work at the same time. Control panels and automation help all the parts work well together. This setup helps fluids move better and keeps everything safe.

Note: The way the inside paths and pipes are set up changes how much fluid the manifold can hold and how well it works.

Manifolds are very important for moving fluids and gases in many jobs. They work like a switchboard, sending flow from one place to many places. Workers use the manifold to choose where fluids or gases go, how fast they move, and when to stop them.

First, fluid or gas goes into the manifold pipes. Valves open or close to send the flow to the right spot. Sensors and gauges show what is happening, so workers can act fast. This helps make the flow just right, saves fluid, and keeps things safe.

Manifolds help by:

Letting one source send flow to many places at once.

Using valves to change or stop flow in certain spots.

Stopping leaks and pressure drops by keeping connections tight.

Working with both hydraulic and pneumatic systems for different jobs.

Controlling many valves makes sure each part gets the right amount of fluid or gas. This saves energy and makes it cheaper to set up. The strong steel pipes help the system handle high pressure and heat without breaking.

Manifolds are checked for how well they spread fluids or gases, how much pressure they lose, and how well they handle heat and shaking. Checking and fixing them often keeps them working well. Safety parts like flashback arrestors and control panels give extra safety.

Steel is a great pick for making manifolds in many jobs. It is strong and lasts a long time. Steel does not get damaged by tough weather or hard work. Engineers like steel because it can take high heat and pressure. It does not bend or break easily. This makes steel manifolds safe for big and small systems.

Here is a table that explains why steel works well for manifolds:

Material Advantage | Explanation |

|---|---|

High Tensile Strength | Steel is very strong for its weight. |

Durability | Steel does not warp, crack, or get hurt by weather. |

Corrosion Resistance | Steel does not rust, mold, or get bugs, so it lasts longer. |

Longevity | Steel stays good for many years, even in hard places. |

Maintenance | Steel needs little care because bugs and rot do not hurt it. |

Structural steel can take at least 50,000 psi of pressure. It keeps its shape in earthquakes, fires, and storms. Stainless steel manifolds almost never rust, so they last a long time. Their smooth surface keeps fluids clean, which is important in many jobs. These things show why steel manifolds are good for hard work.

Many materials can be used to make manifolds, like brass, copper, aluminum, and plastic. Each one has good and bad points. Steel and carbon steel are very strong and work well in hot places. Stainless steel does not rust as much as regular steel. This makes it good for chemical plants and wet places.

Brass and copper manifolds do not rust much. Copper is easy to shape and does not burn, so it is safe for heating and cooling. Brass lasts a long time and does not rust, but it can cost more than steel. Plastic manifolds are light and cheap, but they can break more and need more fixing.

Here is a table that compares costs and features:

Cost Aspect | Steel Manifolds | Aluminum Manifolds | Composite Manifolds |

|---|---|---|---|

Raw Material Cost | High | Moderate | High |

Machinability | Harder | Easier | Complex |

Manufacturing Cost | High | Lower | High |

Maintenance | Low | Low | Moderate |

Durability | Very High | Moderate | High |

Steel manifolds may cost more to make, but they are strong and last a long time. This often makes them a better deal over time. Stainless steel is the best mix of strength and rust resistance for most factory jobs.

In-line manifolds have a straight shape. They link several manifold pipes in a line. This design saves space and helps control flow easily. Factories like in-line manifolds because they fit in small areas. These manifolds let workers handle many pipes at once. Each pipe can send fluid to a different place.

Smart manifolds give even more control. They have sensors and electronic parts inside. These features let workers watch and change flow from a panel. Smart manifolds help save energy and cut costs. They also make it easier to find system problems. Easywell makes both in-line and smart manifolds. Their designs work well for heating, water, and factory systems.

Smart manifolds make things safer and more reliable. They help workers check every pipe and find leaks quickly.

Hydronic manifolds are important in heating systems. They use pipes to move hot water to different rooms. Hydronic manifolds often have flow meters and shut-off valves. These parts help control the heat in each area. Easywell’s hydronic manifolds use strong steel. They do not rust and last a long time, even in big buildings.

Other manifolds can be made from brass or aluminum. Brass manifolds are good for smaller systems. They are easy to shape and put in place. Aluminum manifolds are light but cannot take high pressure like steel. The best choice depends on the job and system size.

Here is a table that compares hydronic steel manifolds with other types:

Feature/Aspect | Hydronic Steel Manifolds | Brass Manifolds |

|---|---|---|

Main Material | Stainless steel | Brass |

Weight | Lighter | Heavier |

Corrosion Resistance | Excellent | Very good |

Pressure Tolerance | Medium | Higher |

Best Use | Large heating systems | Small to medium systems |

Special Features | Flow meters, shut-off valves | Air vents, flow indicators |

Easywell’s manifold pipes can fit many system sizes. Some manifolds need workers to change them by hand. Others use automatic controls for fast changes. This helps factories and buildings pick the right manifold for every job.

Steel manifolds are important in heating and water systems. Many heating and cooling projects use them to move water or heat fluid. Stainless steel manifolds last a long time and control flow well. They help spread water evenly in hydronic systems. This makes rooms more comfortable and saves energy. For example, Easywell’s steel manifolds work in floor heating and solar water heating. They do not rust and last for many years. This makes them good for homes and big buildings. Some types, like chevron-hydroformed manifolds, move heat better than smooth ones. They can increase heat transfer by almost 30%. These manifolds can use flow meters and shut-off valves. These parts make it easier to run the system. Manifold pipes need less fixing and make the system work better.

Factories and plants use steel manifolds to move fluids and gases. They send liquids from one place to many spots or collect from many places. This helps control flow and stops leaks. Many systems use stainless steel because it does not rust and can take high pressure, up to 6000 psig. Manifolds here have valves, fittings, and pressure tools. They help keep flow paths neat and make fixing things easier. Fewer joints mean fewer leaks and safer systems. These things make steel manifolds a top pick for oil and gas, chemical plants, and making things.

Car makers use steel manifolds in exhaust and intake systems. These parts help engines work better and use less fuel. New cars need manifolds that can take high heat and do not rust. Many makers now use stainless steel and strong alloys, not cast iron. Other jobs, like planes, HVAC, and medical tools, also use steel manifolds. In these jobs, manifolds help move fluids and gases in small spaces and under strict safety rules. Manifolds are used to control refrigerant in HVAC and send fuel in planes. As technology gets better, makers use new ways like additive manufacturing to make light, complex manifolds. These changes help meet tough rules and keep things working well in hard jobs.

Steel manifolds help move fluids and gases safely in many jobs. They have many good points:

Systems look neater and are easier to follow

They use less energy and save power

It costs less to put them in and fix them

There are fewer leaks, so they work better

Steel is easy to recycle, so it is better for the planet

Steel works well in hard places because it is strong and safe. Easywell’s Steel Manifold series gives workers a tough and useful choice for new or old systems.

A steel manifold helps control how fluids or gases move. It links many pipes together in one system. This makes it simple to decide where fluids should go.

Steel is very strong and does not rust easily. It can handle high heat and pressure. This makes it a safe and lasting choice for many jobs.

Steel manifolds are used in heating and water systems. They are also found in factories, car engines, and medical tools. These manifolds help move fluids and gases safely.

Easywell’s Steel Manifold spreads hot water in heating systems. It is made from strong carbon steel that does not rust. This keeps homes and buildings warm and safe for a long time.