In today’s high-efficiency heating, cooling and water distribution systems, traditional passive manifolds are no longer enough. Smart manifold systems incorporate sensors, actuators, monitoring and digital control to optimise flow, pressure and energy use across zones. At Jiangsu Easywell Smart Products Co., Ltd., our smart manifold lineup is designed to deliver full automation, precise balancing and seamless integration with expansion tank brackets, valves and controls.

Automated Flow & Pressure Control — integrated balancing valves and electronic actuators ensure each circuit gets the right flow at the right time.

Built-in Monitoring & Feedback — pressure gauges, flow meters and sensor ports let you monitor system health in real-time.

Plug-and-Play Kits — preassembled manifold modules that reduce installation time and minimise onsite complexity.

Future-Proof Compatibility — designed to integrate with building management systems (BMS), IoT controls and expansion tank support modules.

Scalable for Any Size — from compact medium-scale hydronic panels to large industrial floor-heating networks, our smart manifolds scale intelligently.

| Segment | Description | Typical Use Cases | Key Features |

|---|---|---|---|

| Compact Floor-Heating Smart Manifold | Built for mid-scale zones and retrofit residential systems needing automation. | Apartment blocks, smart homes, modular fire-heating units. | Compact footprint, pre-loaded actuators, ready-to-connect. |

| Heavy-Duty Floor-Heating Smart Manifold | High-capacity design for large hydronic loops and commercial systems. | Hotels, schools, large floor-heating zones. | High flow rating, rugged frame, smart control port integration. |

| Industrial Grade Smart Manifold & Bracket Kit | Fully integrated module combining smart manifold with expansion tank bracket for heavy-load systems. | Factories, process heating, large-scale HVAC plants. | Extreme durability, high-load capacity, full automation. |

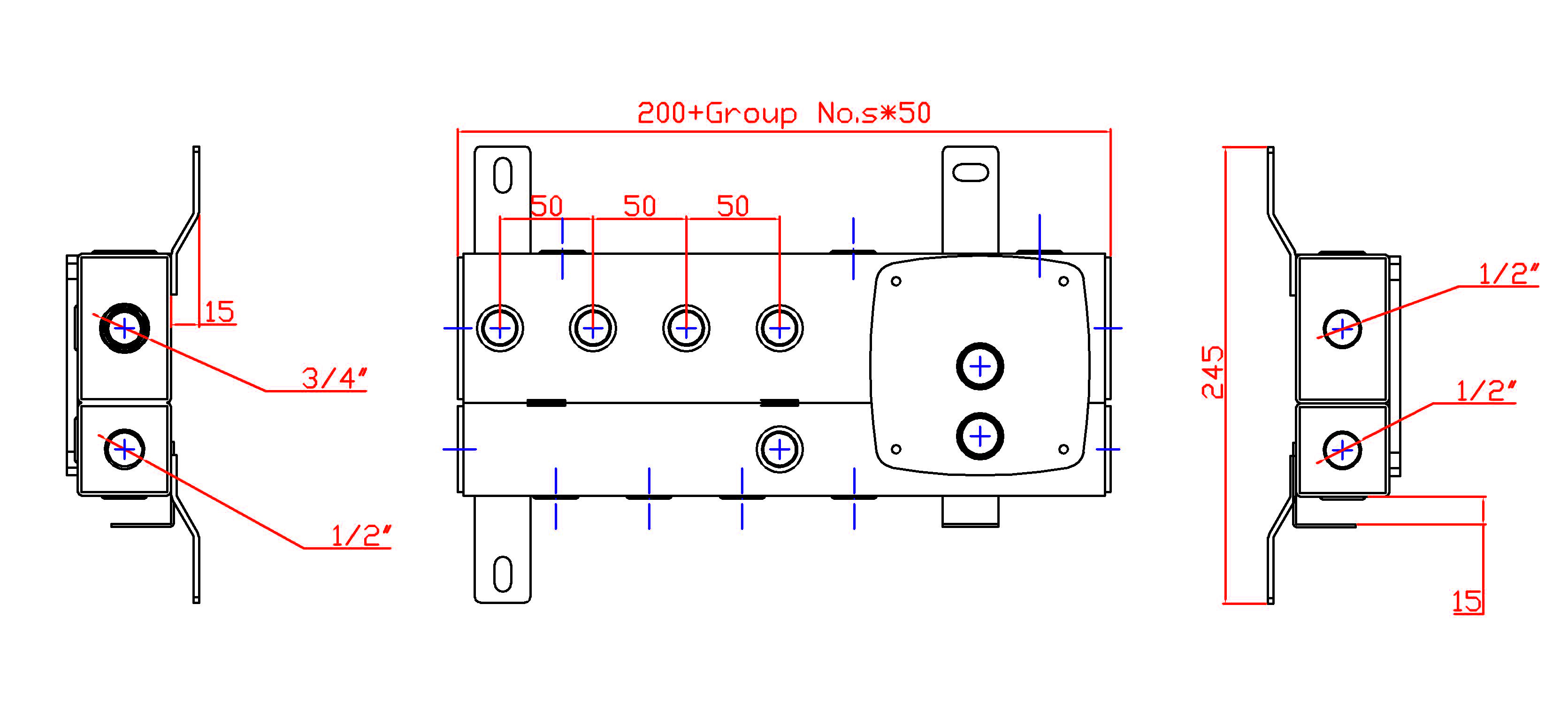

This technical drawing illustrates the heavy-duty floor heating manifold designed for large hydronic and commercial systems.

Key dimensional and structural features include:

Total length: 200 mm (Group No.= ≤ 50 circuits)

Connection ports: ¾″ (main inlet/outlet) and ½″ (distribution circuits)

Mounting height: 245 mm with reinforced side brackets for wall or cabinet installation.

Port spacing: 50 mm intervals for consistent flow distribution across multiple circuits.

Precision layout: ensures equal hydraulic resistance between circuits, improving balancing accuracy in large-scale heating systems.

This version is ideal for industrial and large-building hydronic installations requiring high flow capacity and robust construction.

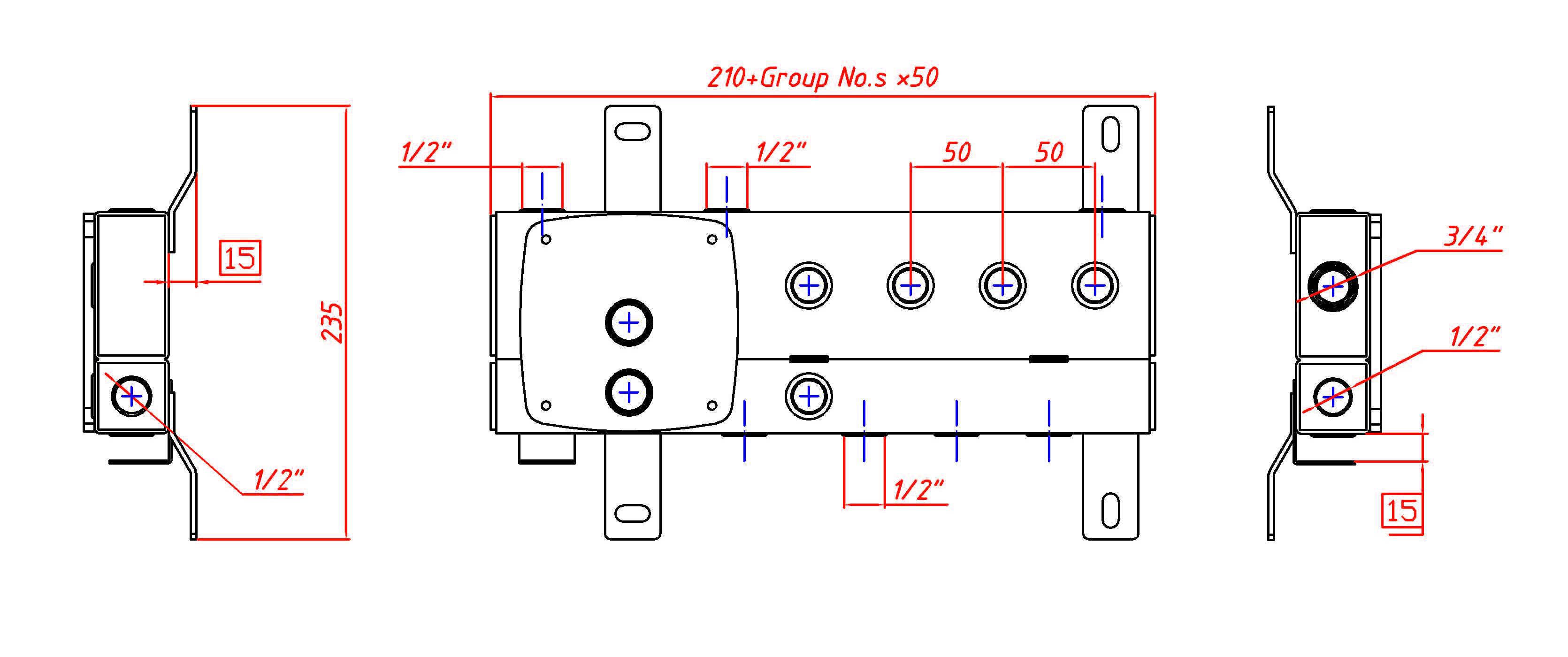

This schematic shows the compact smart floor heating manifold, optimized for medium-sized residential or commercial applications.

Main specifications visible in the diagram:

Overall length: 210 mm (Group No.= ≤ 50 loops)

Circuit spacing: 50 mm between distribution ports for streamlined connection.

Connection size: ½″ ports with ¾″ return outlets, supporting both PEX and multilayer piping.

Mounting height: 235 mm, featuring compact vertical spacing to fit smaller control cabinets.

Integrated sensor module area: reserved for actuator or smart-control installation.

This compact configuration balances performance and size, offering an excellent solution for retrofits or mid-range systems requiring automation and efficient temperature zoning.

Circuits: 4-12 loops (expandable)

Connection Sizes: ¾″, 1″, 1¼″ threaded or flanged

Materials: Carbon steel, stainless steel, brass-composite

Operating Pressure: Up to 16 bar / Working Temp: –20 °C to +120 °C

Sensor & Actuator Ports: 0–10 V, 4-20 mA, BACnet / Modbus interfaces

Compatible with Easywell expansion tank brackets and vessel supports

Residential & Multi-Family Heating: Zoned floor-heating, heat-pump coupling, smart home control.

Commercial Buildings: Automated BMS integration for hotels, offices, health-care facilities.

Industrial & Process Networks: High flow, heavy load, 24/7 operation, with advanced monitoring and maintenance alerts.

Energy & Renewables: Integration with solar thermal, geothermal loops, district energy modules — smart manifold acts as central control hub.

Mounting: Secure manifold module indoors or within mechanical panel. Ensure wiring conduit access for sensors/actuators.

Electrical & Control Integration: Connect actuators to control panel or BMS. Configure sensors for flow/pressure monitoring.

Hydronic Connection: Connect supply/return headers, attach expansion tank bracket, bleed air and fill system.

Setup & Balancing: Use built-in valves and flow meters to calibrate each circuit automatically or via software.

Commissioning: Run diagnostics, verify actuator response, save baseline data for predictive maintenance.

Greater Efficiency: automated balancing means less waste and better comfort.

Fewer Manual Steps: easier installation, less field labour.

Better Monitoring: smart-enabled for proactive maintenance and remote diagnostics.

Scalable & Retrofit Friendly: integrate into existing systems or new builds without major disruption.

It includes electronic control (actuators, sensors, flow feedback) enabling automated flow and pressure regulation, rather than purely manual balancing.

Yes — compact models are designed for retrofit zones, and smart modules can overlay existing piping with minimal changes.

Yes — many models support common interfaces (0–10 V, 4-20 mA, Modbus, BACnet) for BMS integration.

They’re highly recommended — pairing manifold with a dedicated expansion tank bracket stabilises pressure fluctuations and enhances system life.

Periodic check of actuators, flow meters and sensors; calibration every 12-24 months; ensure firmware (if any) is up to date.