The Easywell Square Expansion Tank Bracket Series combines structural rigidity, geometric stability, and modular adaptability for residential, commercial, and industrial heating systems.

The square cross-section design minimizes torsion and vibration while providing superior wall-mount strength — perfect for compact hydronic and retrofit installations.

Square Tube Structure (35×35 mm / 40×40 mm)

Provides exceptional rigidity and minimal flex under dynamic load.

Precision-Welded Frame

Ensures long service life in high-pressure hydronic environments.

Anti-Corrosion Options

Available in stainless steel and epoxy-coated finishes for durability in humid or outdoor installations.

Modular Mounting System

Compatible with retrofit hydronic loops and compact heating units.

Compact Profile

Ideal for space-saving installations in residential and multi-unit applications.

Lightweight, compact, and easy to install in confined technical rooms or behind boilers.

| Product | Core Material | Tube Size | Key Feature | Link |

|---|---|---|---|---|

| Space-Saving Square Expansion Tank Bracket for Residential Hydronics | Steel | 35×35 mm | Low-profile frame for narrow spaces | View Product |

| Modular Square Expansion Tank Bracket Kit for Residential Retrofits | Carbon Steel | 35×35 mm | Adjustable modular kit for retrofit systems | View Product |

| Square Expansion Tank Bracket Kit for Compact Hydronic Systems | Steel | 35×35 mm | Ideal for small-capacity hydronic setups | View Product |

| Compact Square Expansion Tank Bracket for Small-Scale Systems | Stainless Steel | 40×40 mm | Enhanced load capacity for compact HVAC systems | View Product |

Built for continuous-duty systems where mechanical strength and corrosion resistance are critical.

| Product | Core Material | Tube Size | Application | Link |

|---|---|---|---|---|

| Heavy-Duty Square Expansion Tank Bracket for Commercial Systems | Stainless Steel | 40×40 mm | Reinforced frame for large boilers | View Product |

| Corrosion-Resistant Square Expansion Tank Bracket for Harsh Environments | Epoxy-Coated Steel | 40×40 mm | Anti-corrosion coating for coastal or chemical environments | View Product |

| Square Expansion Tank Bracket Stainless Steel 40×40 | Stainless Steel | 40×40 mm | Industrial-grade bracket with smooth finish | View Product |

| Square Expansion Tank Bracket Kit Stainless Steel 40×40 | Stainless Steel | 40×40 mm | Fully assembled kit for industrial and hydronic systems | View Product |

| Product | Tube Dimension | Connection Type | Wall Mount | Link |

|---|---|---|---|---|

| Square Expansion Tank Bracket Kit (Steel 35×35) | 35×35 mm | ¾″ Male + ½″ Female | Flat-wall mount | View Product |

| Square Expansion Tank Bracket Kit (Stainless Steel 40×40) | 40×40 mm | ¾″ + ½″ + ¼″ Ports | Reinforced welded base | View Product |

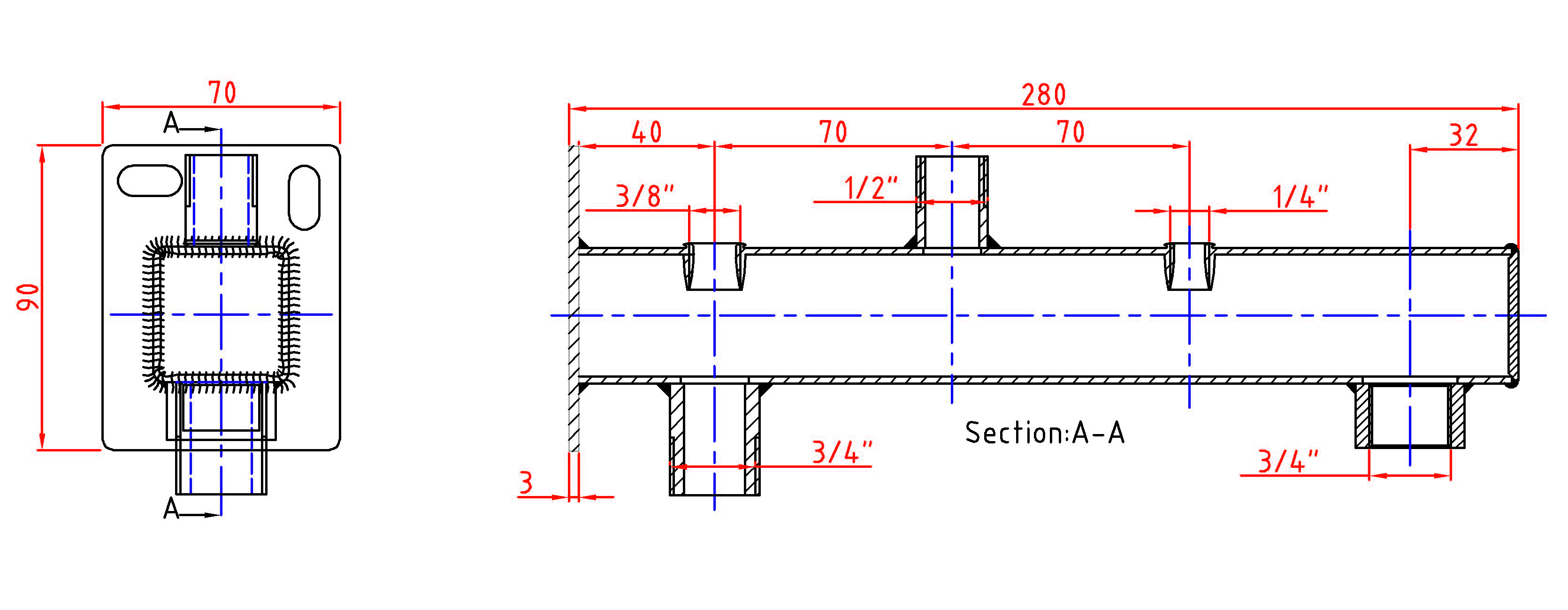

What it shows: ultra-compact square-tube bracket with multi-port top row and dual ¾″ outlets below.

| Specification | Description |

|---|---|

| Length | 280 mm |

| Top Ports | 3/8″ → 1/2″ → 1/4″ |

| Interval Spacing | 40 mm / 70 mm / 70 mm / 32 mm |

| Wall Plate Size | 90 × 70 mm |

| Bottom Outlets | 2 × 3/4″ |

Best for: tight boiler cupboards needing full functionality in a short frame.

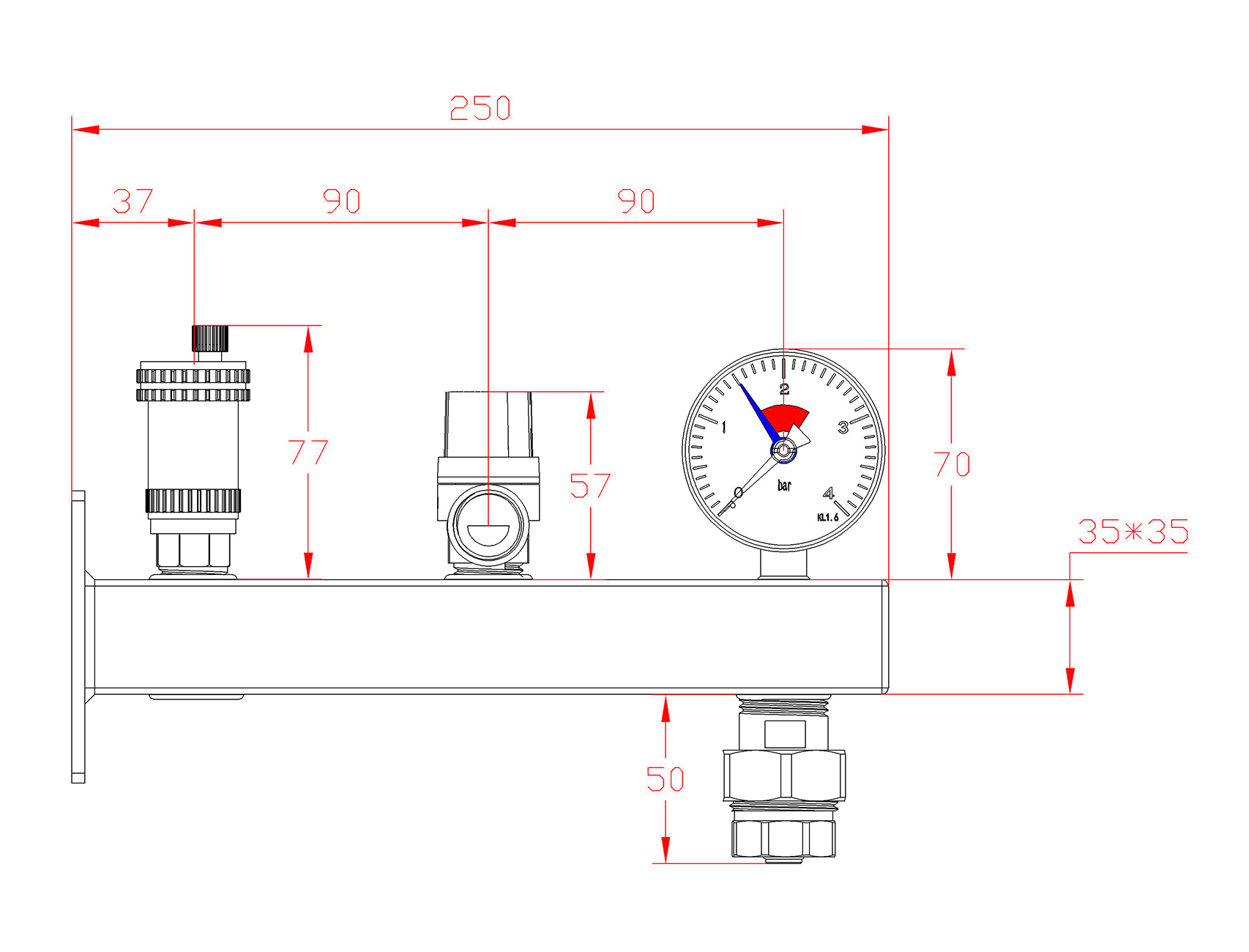

What it shows: 35×35 mm square section with gauge/valve/air-vent layout and short overall length.

| Specification | Description |

|---|---|

| Length | 250 mm |

| Tube Size | 35 × 35 mm |

| Port Spacing | 37 mm – 90 mm – 90 mm |

| Component Heights | 77 mm / 57 mm |

| Outlet Drop | 50 mm |

Best for: small hydronic loops where a Steel 35×35 profile keeps weight and depth low.

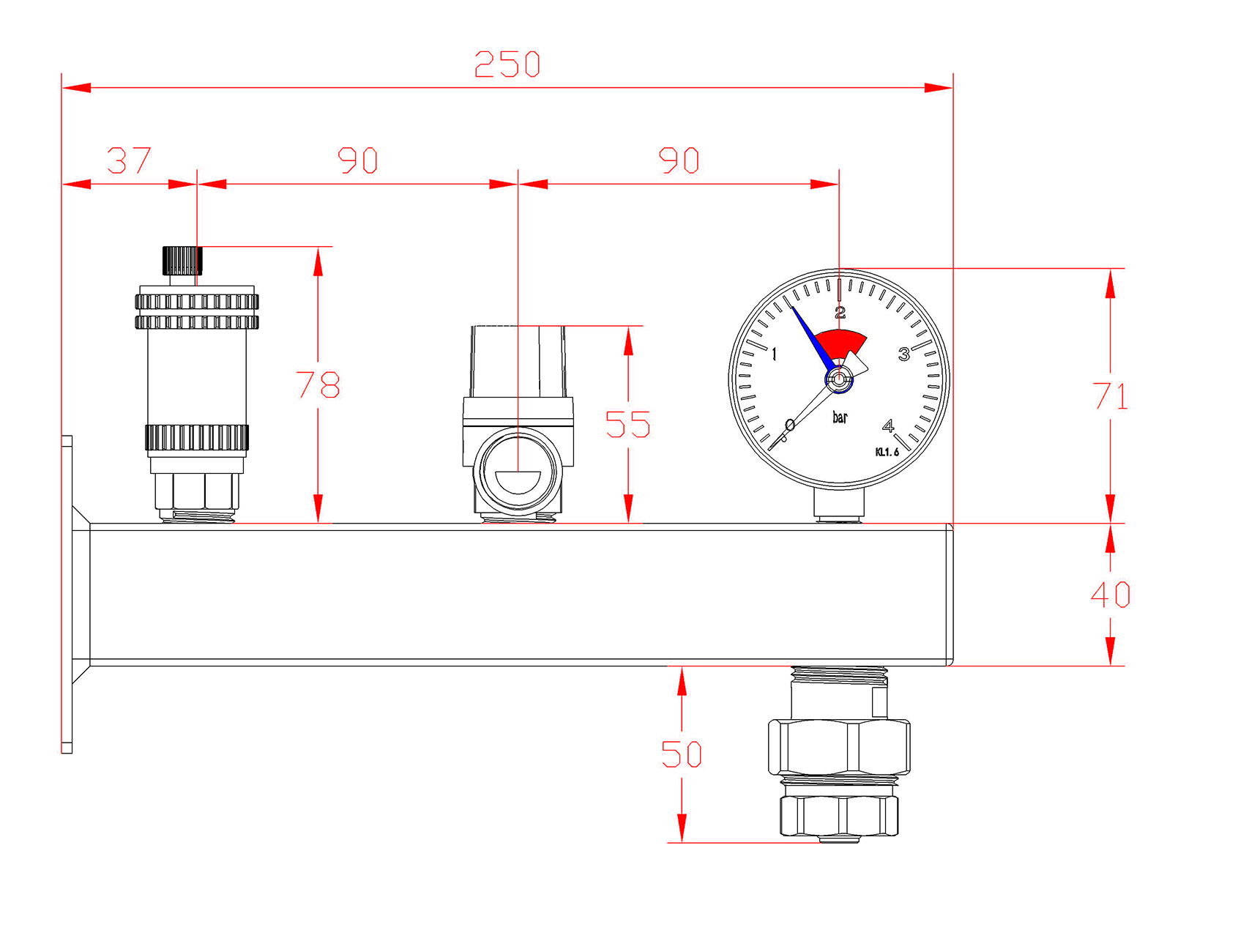

What it shows: stainless 40×40 frame with identical 90 mm module spacing, higher component clearance.

| Specification | Description |

|---|---|

| Length | 250 mm |

| Tube Size | 40 × 40 mm |

| Port Spacing | 37 mm – 90 mm – 90 mm |

| Component Heights | 78 mm / 55 mm |

| Top of Gauge Height | 71 mm |

Best for: corrosion-sensitive installs (coastal/humid) that still need a compact 250 mm layout.

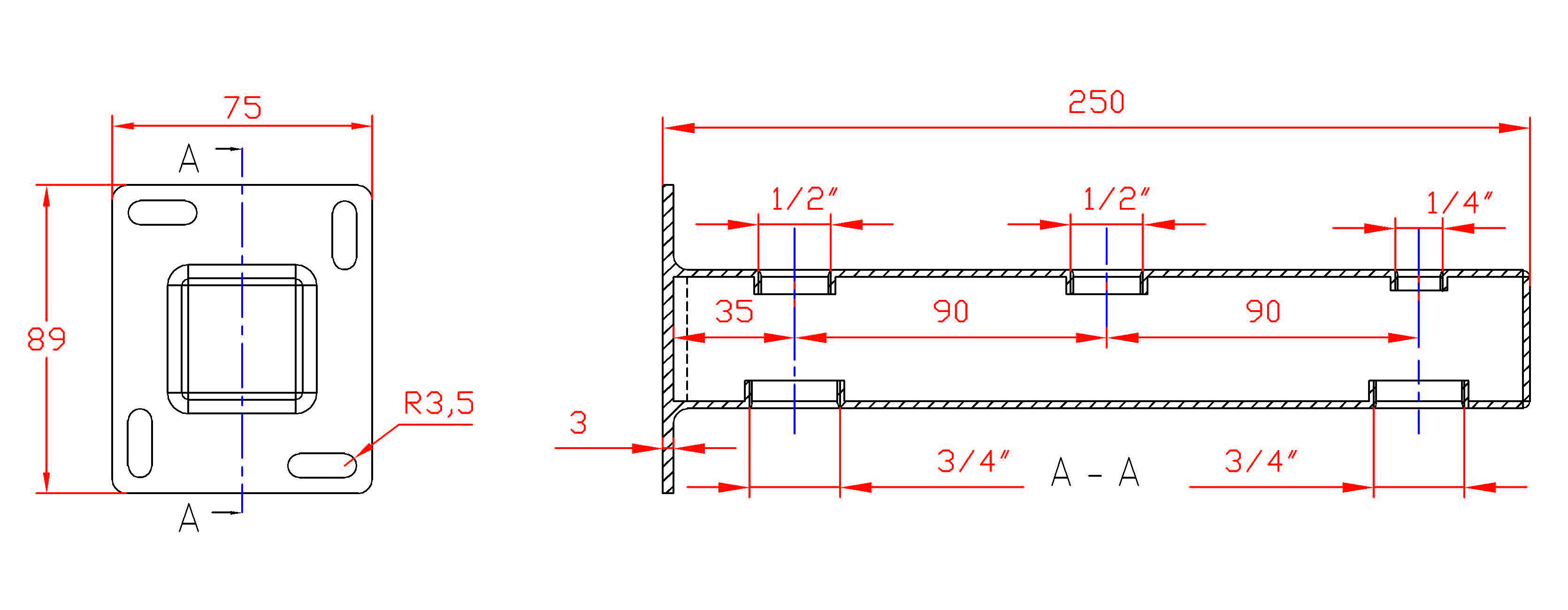

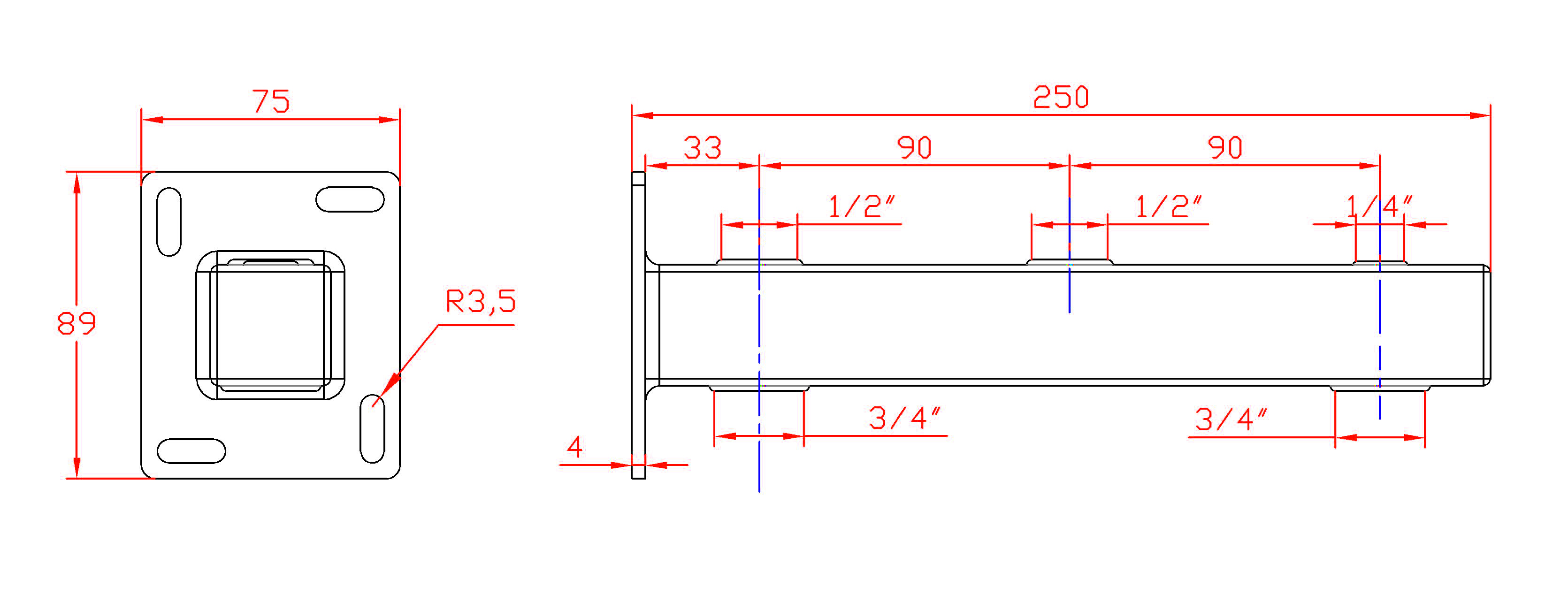

What it shows: sectional view (A-A) with precise port sizes and wall-plate geometry.

| Specification | Description |

|---|---|

| Length | 250 mm |

| Top Ports | 1/2″ – 1/2″ – 1/4″ |

| Bottom Ports | 2 × 3/4″ |

| Port Spacing | 35 mm / 90 mm / 90 mm |

| Wall Plate | 89 × 75 mm × 3 mm thick |

Best for: OEM panels needing 40×40 rigidity and exact threaded take-offs.

What it shows: side elevation with flange thickness and first-port setback highlighted.

| Specification | Description |

|---|---|

| Length | 250 mm |

| First Port Distance from Flange | 33 mm |

| Port Spacing | 90 mm |

| Bottom Ports | 2 × 3/4″ |

| Flange Thickness | 4 mm |

| Wall Plate Size | 89 × 75 mm |

Best for: small-scale hydronic/HVAC skids where flange stiffness (4 mm) and short run matter.

Tube Profiles: 35×35 mm (carbon steel) / 40×40 mm (stainless steel)

Working Pressure: up to 10 bar

Mounting: wall flange with dual-slot alignment

Coatings: zinc-plated / stainless / epoxy

Standard Threads: ¾″ main outlet, ½″ auxiliary, ¼″ gauge port

Operating Temperature: –10°C to +110°C

Mounting Surface: Ensure flat, solid wall base — concrete or reinforced steel recommended.

Anchor Type: Use M8 or equivalent expansion bolts with corrosion protection.

Connection Seal: Apply PTFE or anaerobic thread sealant for long-term leak resistance.

Inspection: Check every 6 months for tightness and corrosion; reapply protective coating if used outdoors.

Replacement: Replace if deformation >2 mm or corrosion depth exceeds 10% of tube wall.

The square design provides greater torsional resistance and rigid mounting for compact systems, while round brackets are preferred for cylindrical or heavy expansion tanks.

Yes, especially the stainless steel 40×40 mm and epoxy-coated models — both designed for high humidity and salt-rich environments.

Absolutely. The Modular Square Kit features pre-drilled flanges and adjustable joints for integration with existing wall manifolds.

Use 35×35 mm for residential or compact systems; choose 40×40 mm for commercial or high-pressure industrial environments.